- 1New Home Sewing Machine Model Identifications

- New Home 692 Sewing Machine Manual Free

- New Home 632 Sewing Machine Manual Free

- New Home 632 Sewing Machine Manual Instructions

- New Home Janome 632 Sewing Machine Instruction Manual

- New Home 532 Sewing Machine Manual

- New Home 632 Sewing Machine Manual Pdf

This is not a difficult piece to find. Like Janome, the new Home bobbin size is set in class 15. All the models made under this brand use the same size bobbin so if you own more than one new Home machine you can take the bobbin out of the good one and replace it without delaying your sewing time. Free online sewing machine manuals used sewing machines and much more at Sewing Online. Instruction Manual for a Newhome 632 Sewing Machine.

by Claire Sherwell

There are over 160 pictures of New Home sewing machines in the NeedleBar Picture Library. While this page is being developed please refer to pictures and information from there: New Home Sewing Machines, the Johnson, Clark & Co Album and the Gold Medal Album.

Early Models

Early company history may be found in the NeedleBar New Home topic in the Makers Forum

For information about early models (Original model, Dolly Varden, Home Companion, Improved Home Shuttle) see the Home Shuttle Survey

The Gold Medal Company manufactured machines for Johnson Clark & Co., the predecessor to the New Home Company of Orange, Mass. Previously the company grew out of partnerships of Thomas H White/William L Grout, then White/Barker, then Clark/Barker.

The Improved Home Shuttle treadle on the left has a last patent date of July 28, 1868 belonging to its inventor, Stephen French. It was witnessed by A J Clark of Johnson Clark who became New Home's President, and John W Wheeler, who was to become the Treasurer and Secretary of New Home.

Prices: No. 1 - Intended to be used as a Hand Machine. It is also adapted for use on Table and Treadle, which will be furnished at any time for $12. It is capable of doing all that can be done on any Family Sewing Machine. $25.

No. 2 - Machine mounted on an Ornamental Iron Stand, with Black Walnut Top, Oil finish. Where a large amount of sewing is required, it is preferable to run the Machine with the Treadle. $37.

No. 3 - The same as No. 2, with the addition of a Cover to protect the Machine from dust when not in use. It is a very desirable style. $42.

No. 4 - Highly Ornamented and has four drawers and drop leaf. $52.

No. 5 - Machine with a full Cabinet Case, Black Walnut, Oil Finished or Polished, as ordered. The Machine and Case are finished in the Highest Style of the Art. $80.

The improved model was designed for family and light manufacturing purposes, sewing the lightest muslins to the heaviest cloth. 'The only practical low-priced lock stitch sewing machine ever invented.' It was guaranteed for five years.

Each machine was supplied with a shuttle, three extra bobbins, a hemmer and feller, braider, screwdriver, five needles, gauge, directions (English, German, French or Spanish) and clamp.

Lockstitch machine. If the machine has R.K. stamped onto it, the initials are thought to be the British importer and distributor Rennick, Kelmsley & Co.

A chainstitch machine.

This Gold Medal was also produced with a rectangular stitchplate. Now a true collectible, but at the time it was manufactured to fulfill a low cost machine for people unable to afford better quality machines such as Singer and Wheeler & Wilson.

The Beginnings of the New Home Line

Orange is beautifully situated among the hills of Franklin Co., Mass., on the Vermont and Massachusetts Rail Road, about ten miles from the Connecticut River. It is a thrifty and prosperous village of about 4,000 inhabitants, lying on both sides of Miller's River.

The Poosac Tunnel Line runs directly through the village, offering special advantages for transportation. Very low rates of freight can be obtained to all points.

Quite a variety of manufacturing is carried on in Orange. The most important industry is the New Home Sewing Machine Works, the history of which dates back to 1860.

Their shops are very extensive, containing nearly 200,000 square feet of flooring. An iron bridge spanning the river connects them with the foundry, which is 300 feet in length, and smelts between 15 and 20 tons daily. In view of the large increase of trade, a new furnace has been added capable of fusing 25 tons of iron at one heat, and making the foundry the best equipped in this part of the State. In 1879 a large fire swept away the buildings in which the cabinet work was made, but they have been replaced by larger and better ones. The Company have in the past year more than doubled their manufacturing capacity and are now turning out over 350 machines per day, giving employment to 600 men.

Pictures of the present day New Home Factory.

Vibrating shuttle, round tension on top of arm instead of the later top tension. Made by Johnson, Clark before the name change to New Home Sewing Machine Company.

Made by Johnson, Clark before name change to New Home Sewing Machine Co. Known simply as The Light Running New Home. The designation of Model A came later.

Key features: Vibrating shuttle using boat shuttle, square corners to bed, top tension without release lever, round needle and presser foot bars, simple 'spooler' instead of automatic bobbin winder, stitch regulator on bed without surround, different styles of presser lifter, note style of take up and shape of rear inspection plate. Socket feet attached by simple screw to rear.

Interchangeable Needles: 20x1 - Boye 4 - Schmetz 35:11 - Free BB - Brewer G - Torrington R - European 712

Early Instruction Manual or Instruction Manual

Made by Johnson, Clark before name change to New Home Sewing Machine Co. Known simply as The Light Running New Home.

Key features: Vibrating shuttle using cylinder shuttle, square corners to bed, top tension without release lever, flat needle bar, simple 'spooler' or later automatic bobbin winder, introduction of new presser foot lifter, feet attached by simple screw to rear, stitch length regulator on bed, note two styles of take up and shape of rear inspection plate. Lily of the Valley or Meadow Weeds decals with 'New Home' bed decal.

Interchangeable Needles: 20x1 - Boye 4 - Schmetz 35:11 - Free BB - Brewer G - Torrington R - European 712

Late 19th/20th Century New Home Machines

The vast majority of New Home machines have the serial number on a Slide Plate.

Earlier models are often referred to by the 'class' name eg New National, which became the model U, then US.

After the Free Sewing Machine Company took over New Home some models were sold under both the New Home and Free names (as well as other badged names). New Home machines started to use letters in front of their serial numbers in about 1930. The letters represent the model type. This applied to all models, including those with a Badged Name.

'New Home' models include: AC, AD, DA, DNHM, JL, KK, LN, M, MS, NH, NHR, NHL, NLR, TS, U, US, NLB.

Free produced models with the following designations (note duplications): A, AD, AAE, AE, ALE, ALR, AN, ANR, ARE, C, CCE, CE, DARE, FH, G, GE, K, KE, L, LE, N, NE, NMO, M, MM, ME, MO, P, PE, W, XE, ALB. For further information about Free Sewing Machine models, see the NeedleBar Picture Library.

Demise of New Home, National & Free

Needle information is taken from Mr NeedleBar's Needle Book compiled by Chrys Gunther, in which additional interchangeable needle makes and information about these models will be found. In many cases a 15x1 (2020) needle may be used in place of 20x1 and set slightly down.

Key features: Vibrating shuttle, rounded corners to bed, top tension with release lever, flat needle bar, stitch length regulator on bed, wide shank shuttle carrier (1/2' wide), note take up and shape of rear inspection plate.

Interchangeable Needles: 20x1 - Boye 4 - Schmetz 35:11 - Free BB - Brewer G - National C - White B - Torrington R - European 712

Key features: As A1 (vibrating shuttle, rounded corners to bed, top tension with release lever, stitch length regulator on bed, same take up and rear inspection plate), with curved end to flat needle bar, either style of bobbin winder, check for narrow shank shuttle carrier (3/8' wide), note foot holder.

Interchangeable Needles: 20x1 - Boye 4 - Schmetz 35:11 - Free BB - Brewer G - National C - White B - Torrington R - European 712

Key features: Vibrating shuttle, rounded corners to bed, reverted to pointed end flat needle bar, top tension with release lever and new mounting, stitch length regulator on bed, narrow shank shuttle carrier, hand wheel without second hole, note take up and rear inspection plate, bobbin winder.

Interchangeable Needles: 20x1 - Boye 4 - Schmetz 35:11 - Free BB - Brewer G - National C - White B - Torrington R - European 712

Key features: Vibrating Shuttle, top tension, flat needle bar measures 8 1/2' long, narrow shank shuttle carrier, note shape of rear inspection plate. Different belt guards for treadle and electric models.

Interchangeable Needles: 20x1 - Boye 4 - Schmetz 35:11 - Free BB - Brewer G - Torrington R - European 712

Key features: Cam drive rotary machine, a descendant of the Free line, having a tangle free spool pin. Tension on face plate. Reversible stitch regulator is Germanic in appearance. Hand wheels available for treadle or electric models, serial number to rear or pillar. Uses Free rotary bobbin and case, bobbin case base has notched rim with solid center pin.

Interchangeable Needles: 206x13 - Boye 2 1/2 - Schmetz 21:32 - Free CC - Brewer T

Key features: Gear drive rotary machine, a descendant of the Free line. Tension on face plate, stitch regulator on pillar. Hand wheels available for treadle or electric models. Uses Free rotary bobbin and case, bobbin case base has notched rim with solid center pin.

Interchangeable Needles: 206x13 - Boye 2 1/2 - Schmetz 21:32 - Free CC - Brewer T

Key features: Vibrating Shuttle, top tension, flat needle bar measures 9 1/4', high mounted bobbin winder, narrow shank shuttle carrier, stitch length regulator on bed, note shape of rear inspection plate. Bed measures 14 1/4' x 7'.

Interchangeable Needles: 20x1 - Boye 4 - Schmetz 35:11 - Free BB - Brewer G - Torrington R - European 712

Key features: Vibrating Shuttle, side tension (facing operator), round needle bar, capped presser and needle bars, narrow shank shuttle carrier, stitch length regulator on bed, note shape of rear inspection plate.

Interchangeable Needles: 20x1 - Boye 4 - Schmetz 35:11 - Free BB - Brewer G - Torrington R - European 712

Key features: Vibrating Shuttle, side tension (facing operator), round needle bar, capped presser and needle bars, narrow shank shuttle carrier, stitch length regulator on pillar, second hole on hand wheel, note shape of rear inspection plate. See also Model P.

Interchangeable Needles: 20x1 - Boye 4 - Schmetz 35:11 - Free BB - Brewer G - Torrington R - European 712

Key features: Rotary machine, serial numbers up to 3,030,440. E2 from 3,030,440 to 3,787,351. Note spool holder on top of arm. Bobbin case different from subsequent rotary models. Patents from 1904 to 1906.

Interchangeable Needles: 15x1 - Boye 16 - Schmetz 21:46 - Free AA - Brewer 11 - Torrington Y - European 691, 705 - HAx1

New Home 692 Sewing Machine Manual Free

Key features: Rotary machine, E3 and E4 machines have serial numbers from 3,787,351 to 3,820,456. Straight spool pin on arm, stitch regulator plate on bed. Note shape of bed plate swing cap.

Interchangeable Needles: 15x1 - Boye 16 - Schmetz 21:46 - Free AA - Brewer 11 - Torrington Y - European 691, 705 - HAx1

Key features: Rotary machine, E3 and E4 machines have serial numbers from 3,787,351 to 3,820,456. E5, E6 & E7 above 3,820,456. Straight spool pin on arm. Shape of bed plate swing cap as E3.

Interchangeable Needles: 15x1 - Boye 16 - Schmetz 21:46 - Free AA - Brewer 11 - Torrington Y - European 691, 705 - HAx1

Key features: chainstitch machine with automatic tension.

Interchangeable Needles: 1x11/25x1 - Boye 20 1/2 - Schmetz 02:45 - Free ACS - Brewer S - European 63, 64 - WY502

New Home G

Key features: A rotary machine known by New Home as a 'Central Bobbin Rotary' with same shaped bed swing cap as the later rotary models. Stitch regulator on pillar.

Interchangeable Needles: 15x1 - Boye 16 - Schmetz 21:46 - Free AA - Brewer 11 - Torrington Y - European 691, 705 - HAx1

Key features: A Central Bobbin machine. Bobbin case finger points to one o'clock. Belt guard tension discs on hand wheel. 'NHSMCO Rockford, Ill.' diamond decal above the stitch length lever; 'Light Running New Home Trade-Mark' with running dog logo on bed; 'République Française Exposition Universelle, New Home 1889' decal on inside pillar.

Interchangeable Needles: 15x1 - Boye 16 - Schmetz 21:46 - Free AA - Brewer 11 - Torrington Y - European 691, 705 - HAx1

Key features: A Vibrating Shuttle machine with top tension, stitch regulator on pillar, high mounted bobbin winder, low take up on face plate, round needle bar 8 3/4' long. See Model N.

Interchangeable Needles: 20x1 - Boye 4 - Schmetz 35:11 - Free BB - Brewer G - Torrington R - European 712

Key features: This vibrating shuttle machine is unusual for New Home in not having a top tension and the reversible stitch regulator is Germanic in appearance. As a descendant of the Free brands it uses a tangle free spool pin and has a curved take up on the face plate (Free model C). Side (operator facing) tension. Serial number to rear of pillar.

Interchangeable Needles: 15x1 - Boye 16 - Schmetz 21:46 - Free AA - Brewer 11 - Torrington Y - European 691, 705 - HAx1

Key features: Vibrating shuttle machine, top tension, round needle bar measures 8 3/4' long, stitch length on pillar, narrow shank shuttle carrier, note shape of rear inspection plate.

Interchangeable Needles: 20x1 - Boye 4 - Schmetz 35:11 - Free BB - Brewer G - Torrington R - European 712

Key features: Vibrating shuttle machine, side tension (facing operator), note shape of rear inspection plate on left side, take up towards top of face plate.

Interchangeable Needles: 20x1 - Boye 4 - Schmetz 35:11 - Free BB - Brewer G - Torrington R - European 712

Key features: Vibrating shuttle machine, top tension, high mounted bobbin winder, minor changes to R2 (e.g. bed plate), R2 has electrical parts. Round needle bar, 8 1/2' long.

Interchangeable Needles: 20x1 - Boye 4 - Schmetz 35:11 - Free BB - Brewer G - Torrington R - European 712

New Home T : TS3D, TS3F, US500D, US500F, T3D, T3F, U500D, U500F, XE

Bed measurements: 11 3/8' x 7'. There are several variations of this model of New Home hand crank machines. The main ones are

T1 - Vibrating shuttle, direct drive hand wheel (cheaper to produce), iron base (also cheaper to produce), rack & pinion bobbin winder, top tension, stitch regulator on pillar, note face plate

T2 - Vibrating shuttle, full sized rear inspection plate ('arm cap'), top tension, stitch regulator on pillar, note face plate

T3 - Vibrating shuttle, smaller rear inspection plate, top tension, stitch regulator on pillar, note face plate

Interchangeable Needles for T, U & XE: 20x1 - Boye 4 - Schmetz 35:11 - Free BB - Brewer G - Torrington R - European 712

Interchangeable Needles for TS & US: 15x1 - Boye 16 - Schmetz 21:46 - Free AA - Brewer 11 - Torrington Y - European 691, 705 - HAx1

New Home T2. Photo: Claire Sherwell

New Home T3, Photo: Mark Urban

New Home US, c1931 Photo: Judith Baker

New Home 632 Sewing Machine Manual Free

New Home New National - UKey features: Vibrating shuttle, top tension, stitch regulator on pillar. Hand wheel as shown or variation, also variations in needle bar and bobbin winder (early rack & pinion style also used), as well as bed differences (cheaper iron based option). Bed measurements 11 3/8' x 7'. Produced from the 1880s as their hand machine, through to the 1930s when it became the Model US. A three quarter sized machine hand crank.

Interchangeable Needles: 20x1 - Boye 4 - Schmetz 35:11 - Free BB - Brewer G - Torrington R - European 712

New Home New National, early model, mid 1880s Photo: Claire Sherwell

c1900. Especially adapted for use by tailors, extra large treadle table and base.

Model V, VM - New Home Midget, Little Worker

A vibrating shuttle machine (not chainstitch). Originally called the Little Worker, it became known as the New Home Midget, model V, a small hand machine. Model VM was the small electric version for AC current only. Sold with a table clamp or iron base to make the machine more stable while sewing. Also sold under badged names such as Mother's Helper (by Montgomery Ward) and Baby Sheridan in the US, also UNI in Australia.

The patents of April 4, 1911 and February 13, 1912 were both filed on December 5, 1910 by Orville Kies. Kies was President of the Knickerbocker Hand Sewing Machine Company of New York. Some machines have Knickerbocker on the stitch plate.

Interchangeable Needles: 20x1 - Boye 4 - Schmetz 35:11 - Free BB - Brewer G - Torrington R - European 712

Key features: Vibrating shuttle, tension on face plate, stitch length regulator on pillar, serial number to rear of pillar. Portable electric only.

Interchangeable Needles: 20x1 - Boye 4 - Schmetz 35:11 - Free BB - Brewer G - Torrington R - European 712

© Claire Sherwell 2009

THE NEEDLEBAR

Online Manuals Section

D I R E C T I O N S

FOR USING THE

FLAT TENSION, VIBRATING SHUTTLE

New Home 632 Sewing Machine Manual Instructions

NEW HOME

SERIES A

SEWING MACHINE

Transcribed for the NeedleBar by Helen Scarth

Part One

MANUFACTURED BY

THE NEW HOME SEWING MACHINE CO.,

MAIN OFFICE AND MANUFACTORIES,

New Home Janome 632 Sewing Machine Instruction Manual

ORANGE, MASS., U.S.A.

DISTRIBUTING OFFICES :

N.Y. CITY & EXPORT SALESROOM, 45 EAST 17TH STREET,

UNION SQUARE NORTH

LONDON OFFICE

CHICAGO SAN FRANCISCO

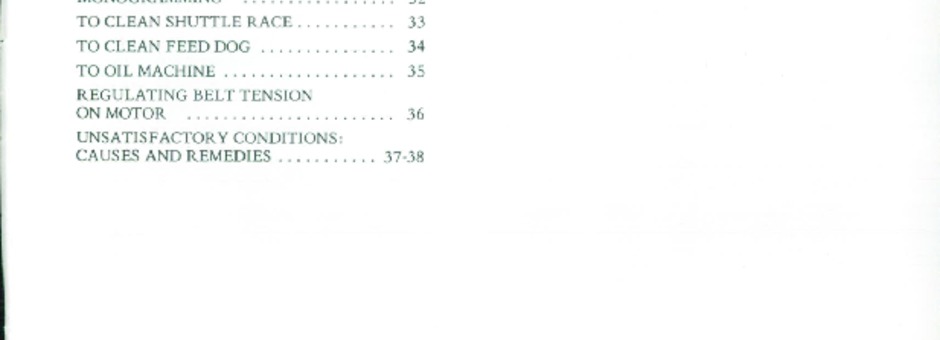

INDEX

| Bed Lock | |

| Belt | 5 |

| Bobbin, How to Wind | |

| Breaking Lower Thread | 7 |

| Breaking Upper Thread | |

| Felling | 12 |

| Foot, To Remove | |

| Foot, To Adjust | 9 |

| Gauge, Use of | |

| General Remarks | 2 |

| Hemstitching | |

| Hemming | 11 |

| Hemming and Sewing on Lace | |

| Important | 2 |

| Illustrated Parts | |

| List of Parts | 14 |

| Missing Stitches | |

| Needles | 5 |

| Needle, To Set | |

| Needles and Thread, To Select | 10 |

| Oil | |

| Outfit | 11 |

| Parts of Stand and Cabinet | |

| Quilting | 13 |

| Sewing, Ready for | |

| Shuttle Ejector | 7 |

| Shuttle, To Thread | |

| Shuttle, To Place | 7 |

| Shuttle Thread, To Draw Up | |

| Stand, To Adjust | 4 |

| Stitch, Length of | |

| Tension, To Regulate | 8 |

| Threading Machine | |

| To Oil Machine | 3 |

| To the Learner | |

| Treadle | 4 |

| Work, To Remove |

FOR OPERATING THE

FLAT TENSION,

VIBRATING SHUTTLE,

NEW HOME

Series A,

Sewing Machine

MANUFACTURED BY

THE NEW HOME SEWING MACHINE CO.,

New Home 532 Sewing Machine Manual

MAIN OFFICE AND MANUFACTORIES,

New Home 632 Sewing Machine Manual Pdf

ORANGE, - MASS., U.S.A.

DISTRIBUTING OFFICES:

N.Y. CITY & EXPORT SALESROOM, 48 EAST 17TH STREET,

(UNION SQUARE NORTH)

LONDON OFFICE: 24 - 26 DENMAN STREET, S.E.

CHICAGO - SAN FRANCISCO

Important

When you receive the machine you will observe a small tag attached to the bed of the machine by the screw which holds the head of the machine in place while in transit. Remove this screw as directed on the tag so the head can be turned back for oiling and cleaning. Do not replace the screw unless you desire to reship the machine, when it should be replaced.

To the Learner

A little time given to the study of the instructions before commencing to use the Machine, will be found of great advantage. Any one can learn to use the New Home. It is simple in construction, and requires so little change for any kind of work, that its operation can be easily understood.

Attention to the instructions here given, and a little practice, will soon enable the learner to successfully operate the Machine.

Do not attempt to use the Attachments until you can manage the Machine with ease on plain sewing.

The cause of a machine not working properly may be due to poor thread, or a size too large for the needle, or in the wrong adjustment of the tension.

If at any time the Machine fails to perform its work properly refer to the instruction book to ascertain the cause. This will help you out of the trouble if you carefully follow the directions.

For example, if your machine misses stitches, you turn to the index: (inside front cover) 'Missing Stitches.' On page 8 you read, 'Should there at any time be skipped or long stitches at intervals, it is owing to the needle being set too low, or its having become best away from the shuttle, or its being too small for the thread in use, etc., etc.' You will therefore be able to easily remedy the trouble. We advise a careful perusal of 'General Remarks'.

General Remarks

The presser foot must never be let down on the feed, unless when you are sewing and have cloth under it. When the shuttle is in, the machine must not be run with either of the shuttle slides out or partly open as the shuttle is liable to get out of position and break some portion of the machinery.

We caution purchasers to see that the manufacturers' plate number of the machine is plain and in good condition. If defaced or obliterated, it is sure evidence of fraud, and we will not warrant, or in any way be responsible for such machines. To avoid imposition buy only from us or authorized dealers.

Do not run the machine backward or with both threads in, without sewing.

Do not use a dull or bent needle, or draw the work faster than the feed will naturally carry it, as needles are frequently broken by failing to observe the latter caution.

When ordering parts always give the plate number of machine.

Poor oil is dearer than good oil, because it ruins the parts of the machine and does not last as long. It makes the machine run hard: corrodes and eats into the bearings, making them rough and hard to operate. It clogs and fills up the oil holes, so that, unless the operator carefully and laboriously picks out the holes, the oil cannot penetrate to the bearings and soon the machine begins to run hard. Be sure you get the best.

OIL THE UPPER PARTS AS HERE INDICATED. |

THE BEST OIL IS THE CHEAPEST.

OIL THE UNDER PARTS AS HERE INDICATED.

To Oil Machine

Oil the centers on which the driving wheel of stand turns, and where the foot piece rests on the rod. After the machine has been oiled, run it (with presser-foot up and shuttle out) for a minute, and then wipe off the superfluous oil. If the machine runs hard after standing idle for some time, use a little kerosene oil in the usual way and run rapidly, then wipe clean, and oil with the best prepared oil. Oil the bobbin-winder in places where there is any friction.

The head of the lock is depressed in the front of the bed-place. Push down on the lock head, this will release the machine head so it can be turned back and the parts can be oiled and cleaned.

The Treadle

Familiarity with the motion of the treadle is first to be learned, and practice is necessary in order to give a steady and uniform revolution to the driving wheel. The presser-foot, which holds the work in place on the feed, should be raised to prevent the feed from injury by contact with it. Place the feet on the treadle with instep directly over the rod upon which the treadle rests. Start the machine by placing the right hand upon the top of balance wheel and revolving it towards you, taking care to give it impetus enough; keep up a regular movement by pressing alternately with the heel and ball of the foot with equal effect. This should be practiced until a uniform motion of the wheel is obtained. Do not attempt to sew until you are familiar with the treadle movement.

To Adjust Stand

Every Sewing Machine of our manufacture is perfectly adjusted in all its parts when it leaves our factory. We illustrate below the different parts of the Stand to enable the inexperienced operator to properly adjust any part, should it in any way become loosened.

Should the Foot Plate (K) have nay play from right to left it needs adjusting; loosen the Plug Nut (M3) and adjust the Plug (M2) so that the Foot Plate will work evenly, taking care not to set the Plug too tightly against the Foot Plate to cause it to operate hard; if adjusted properly, it should work but with the slightest pressure. Should the Drive Wheel (E) not run true or evenly, loosen the Drive Wheel Crank Plug Screw (GG) and adjust the Plug so the Drive Wheel (E) has no play, but will run evenly, then screw tight. Should the Pitman (P) work too loose on Pitman Stud (Q), loosen nut on lower end of rod and turn the screw slightly to right and tighten nut.

The Belt

The belt should always be tight enough to prevent slipping. Should it become too loose, cut it to the desired length, observing to make a new hole at right angles with the grain side of the leather, that you may obtain its full strength.

Needles

WE MAKE OUR OWN NEEDLES, therefore, if you cannot get the genuine, with 'NEW HOME' and our trade mark of a Greyhound stamped on the shank, write direct to us. Poor needles are responsible, many times, for skipped stitches.

To Set the Needle

First loosen the screw that clamps the needle and push to the left sufficient to allow the shank to enter; allow the needle (with the flat side of shank towards the needle bar) between the thumb and finger of the left hand, and insert the needle into the groove (as far up as it will go) under the clamp, and screw fast. Observe that the needle passes through the hole in the Throat Plate without touching either side. It it touches, take hold of it near its point, and press it gently in the opposite direction, until it is free.

To Wind Bobbin

Unlock the balance wheel with thumb and forefinger of the right hand by drawing the key (12) out, turning it part around, (this will save the trouble and annoyance of unthreading the needle and removing the work while the bobbin is being filled). Then swing the bobbin winder until it is in position and presses firmly against the belt. Place the spool of thread to be wound from on the spindle (80) and put the bobbin in the bobbin winder. Pass the thread from the spool, once around the tension screw (104) as shown in cut, thence down between the bobbin winder frame and wire guide at (A), then through slot (B) at bottom of thread guide, then into V shaped slot of thread guide at (C). To secure the end of thread preparatory to winding, place it between the head of the bobbin and its socket at the right hand. Proceed as in sewing. When the bobbin has been filled, swing the winder from belt and turn back the key (12) until it enters the hole and locks the balance wheel.

To Thread Shuttle

Take the shuttle in the left hand, with the point toward you; draw off about two inches of thread from the bobbin, thread running from the upper side, (se Fig. 1); drop the bobbin into the shuttle as far as it will go; then draw the thread into the open slot of shuttle, at the same time putting a little pressure with the finger on the end of bobbin; by drawing the thread toward you it will be forced under the point of shuttle spring, (see Fig. 2); then draw it back until it passes over the point; (see Fig. 3); shuttle is ready for sewing. Fig. 4 shows shuttle properly threaded, ready for sewing.

The tension is regulated by turning the screw in point of shuttle to the right or left; to the right to give more tension; to the left, to give less tension.

It will not generally be necessary to change the tension of shuttle for ordinary kinds of sewing.

To Place the Shuttle

Withdraw the front shuttle slide and place the shuttle in the carrier, point first, toward the operator; then close the slide. It is sometimes more convenient to withdraw the back shuttle slide and put the shuttle in its place when the carrier is at the back part of the machine. This is especially the case when some of the attachments are in use.

Shuttle Ejector

Pull out the front shuttle slide and press down on the ejector head, the shuttle will be raised and is easily removed.

Part Two | Part Three | Part Four